- High End Gypsum Board System Solution Provider

In addition to budget design and construction, there is also one thing that every homeowner is particularly concerned about but uncertain about in home decoration, which is the construction period. Even a small two bedroom apartment can take two to three months to renovate at home, and a large villa can start within six months. Everyone wants to follow the contract process after signing the contract, try to complete and deliver within the agreed deadline, and also have to open windows for ventilation and complete soft furnishings to move in as soon as possible. What is the reason for the delay in home decoration schedule, and what methods can be used to avoid it? Jason's gypsum board editor will analyze the details in detail.

In fact, it is most important to clarify the reasons for the delay. After all, as a decoration company, the reasonable logic is to complete your home as soon as possible, arrange the construction team to the next construction site, the company can earn money, the foreman can earn money, and the speed should be fast to make people and money turn around. So it is not reasonable for decoration companies to subjectively delay the construction period. On the contrary, they hope that the faster the better, and on the contrary, you need to consider the issue of slow work leading to meticulous work.

What is the reason for the delay in the project schedule? There are generally the following situations:

1. The construction team leader, also known as the foreman or foreman (whose name doesn't matter), intentionally delays your construction schedule due to conflicts with the decoration company. If there are any signs of this situation, immediately request the decoration company to replace the entire construction team, do not hesitate. A slight hesitation is not only a matter of project schedule, but also the possibility of a disastrous construction quality;

2. The construction team leader was greedy and took on too many construction sites at the same time, making it difficult to arrange manpower, resulting in an inexplicable halt in waiting for the construction nodes that originally did not need to wait. It's best to communicate with the construction team leader about this and explain that you are in a hurry, hoping to follow the construction schedule. If you delay, you will have to complain (you can say it in a joking tone). If ineffective, it is also recommended to forcibly replace the construction team;

3. There are problems with the coordination between the auxiliary material agents and main material suppliers cooperating with the decoration company. The auxiliary materials needed at the construction site are not delivered in a timely manner, and the main materials are sent incorrectly and replaced. This includes coordinating with the size review and material supplier to come up with a plan, which is even more complicated. The most common problem in this situation is with on-site customized products, such as cabinets, whole house customization, aluminum alloy window sliding doors, etc. It is not related to the construction team workers, but rather a problem with the material supplier. In this situation, it is necessary to communicate with the decoration company in a timely manner. If there is a complaint or a refund, there is no hesitation. Especially for whole house customization, the success rate of installation for finished products is basically less than 20%, and problems are almost inevitable. But if there are frequent problems twice, three times, and four times, the construction period can be delayed for several months, even longer than the normal construction period, which is very exaggerated.

So knowing these reasons can also lead to a good plan, but what should we do if we still want to shorten the construction period a bit? There is actually a way. Although reducing the decoration process is the best way, it is definitely not recommended to cut corners in the decoration of self occupied residential buildings. Not only that, we also need to consider environmental protection as much as possible, whether it's building materials or craftsmanship, the more environmentally friendly the better.

In fact, the entire process of hard decoration is operated by the construction team leader and frontline workers, and the most time-consuming part is actually the process related to bricklaying. For example, the powder leveling after dismantling, the leveling of the ground and walls, the filling of grooves after water and electricity slotting, and the laying of ceramic tiles and floor tiles all need to be dried and maintained to avoid cement cracking and affecting construction quality. In fact, from a different perspective, these construction processes that require a lot of waiting time can be replaced with processes that do not require waiting or work faster, in order to achieve the final result of shortening the construction period and accelerating the construction speed.

There are several main aspects that can be "construction leveling":

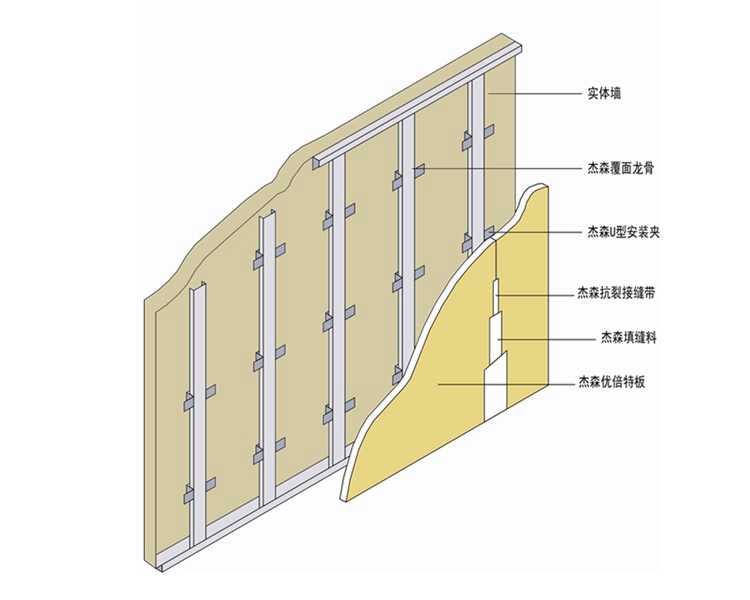

① The powder leveling process of the wall can be completely omitted, and only a layer of gypsum board veneer wall system needs to be applied on the original wall to directly proceed to the next decoration process without waiting. Moreover, it is an assembly type construction with extremely fast speed. Even the slotting process of the strong and weak electrical conduits that were originally intended to be embedded in the wall has been eliminated, and they can be directly embedded in the veneer wall. At the same time, the minimum thickness of the veneer wall can reach 3CM, and it is not much thicker than the second leveling process of the wall, which is completely acceptable;

② The ground doesn't need to be leveled with cement, and there's no need to even make grooves. Simply lay strong and weak electrical conduits on the ground and use gypsum based self leveling to level it. The drying speed of gypsum based self leveling is three times faster than that of traditional cement mortar leveling, and it does not require any maintenance or cracking, making it simple and easy to operate;

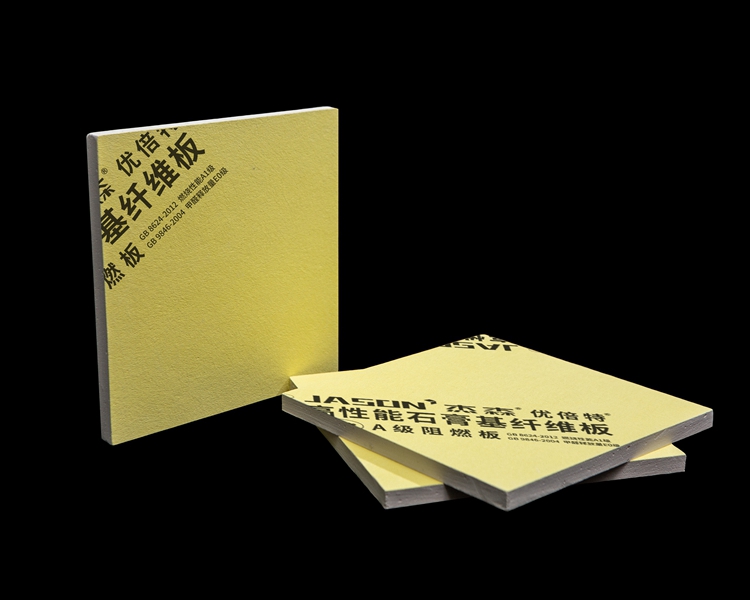

③ All places that require the use of blockboard, such as the base layer of central air conditioning units, ceiling base layer, soft and hard packaging base layer, curtain box base layer, etc., can be directly replaced with environmentally friendly and high grip nail strength Jason Uber high-performance gypsum based fiberboard. Not only does it shorten the construction period, but it is also easy for carpenters to operate. The process of making gypsum boards on the base layer and then the final decorative surface is equivalent to reducing one process. As long as one layer of board surface is made, the final decorative surface can be made.

In summary, while reducing costs, coupled with open source, we control our home renovation schedule from front to back. Jason's gypsum board editor has reason to believe that after reading this informative sharing, you can achieve twice the result with half the effort when decorating your home, and no longer be troubled by project delays.

(Some of the images are from the internet. If there is a possibility of infringement, please contact the editor to delete them.)