- High End Gypsum Board System Solution Provider

Can light steel keel fully replace wooden keel? How to Apply Stylable Light Steel Keels

In architectural decoration engineering, the use of keel is inevitable in the construction of partition walls or suspended ceilings. As a building material that supports the shape and fixes the wall surface layer, it is widely used in fields such as building renovation, interior decoration, and ceiling construction. From a material perspective, there are mainly two types of keel: wooden keel and light steel keel. Aluminum alloy keel, which is less commonly used indoors, can be ignored. What is the difference between light steel keel and wooden keel? Can light steel keel be used to completely replace wooden keel in actual engineering projects? Jason's gypsum board editor will provide a detailed analysis of the gateway in between.

In addition to using wooden keel when laying pure solid wood flooring. The construction projects of various partition walls, ceilings, and ceilings all involve the question of whether it is better to use light steel keel or wooden keel. What is the difference between these two common keel materials? There are mainly the following items.

1、 Durability. The reason why a new product called light steel keel was invented is mainly to solve the problem of insufficient durability of wooden keel. Previously, large engineering projects often used steel structures as structural structures, while small fixtures and home decorations often used wooden keel construction for ceiling partitions. However, the durability of wooden keel construction is really worrying. Therefore, a light steel keel made of cold-formed gadolinium with galvanized steel strip was developed as a substitute, which naturally outperforms light steel keels in terms of durability.

2、 Moisture and mold proof. Another major reason for using light steel keel instead of wooden keel is that after long-term use, especially in areas with high air humidity in the south, wooden beams are prone to mold and mold production. Living in an environment with mold for a long time has a significant impact on physical health. Light steel keel can effectively solve this problem, not only moisture-proof and moldy proof, but also completely worry free when applied in bathrooms and shower rooms. At the same time, light steel keel also effectively avoids the problem of expansion and deformation of wooden keel in humid environments. When used in conjunction with Jason water-resistant gypsum board, it achieves both practicality and aesthetics of bathroom ceiling.

3、 Anti seismic and anti cracking measures. As shown in the above figure, the light steel keel ceiling is connected by suspension rods to support the keel or card type keel. One characteristic of this process is that non rigid connections have a certain degree of adjustability. Compared to the fully fixed connection between the wooden keel gypsum board and the keel and the wall, the light steel keel can more effectively prevent gypsum board cracking in the event of earthquakes or slight ground settlement year-round due to the characteristics of the suspension rod connection.

4、 Insect and environmental performance. This is a common problem faced by the southern region. Although wooden keels can also be soaked in anti-corrosion and insect proof solutions to prevent termite erosion, doing so can also lead to excessive formaldehyde emissions from wooden keels, as the main component of anti-corrosion solutions is formaldehyde. So even for home decoration in the south, it is more inclined to use light steel keel comprehensively, which is also to prevent insect pests.

5、 Stylability. The above few are all light steel keel, but only in terms of formability, it is the world of wooden keel. Due to the characteristics of the material itself, wooden keel can be customized into various curved thickness and irregular shapes, and the operation is relatively simple and direct. However, it is difficult to create curved shapes for light steel keels, so many projects require irregular suspended ceilings with certain durability indicators, and can only choose the process of mixing light steel keels and wooden keels.

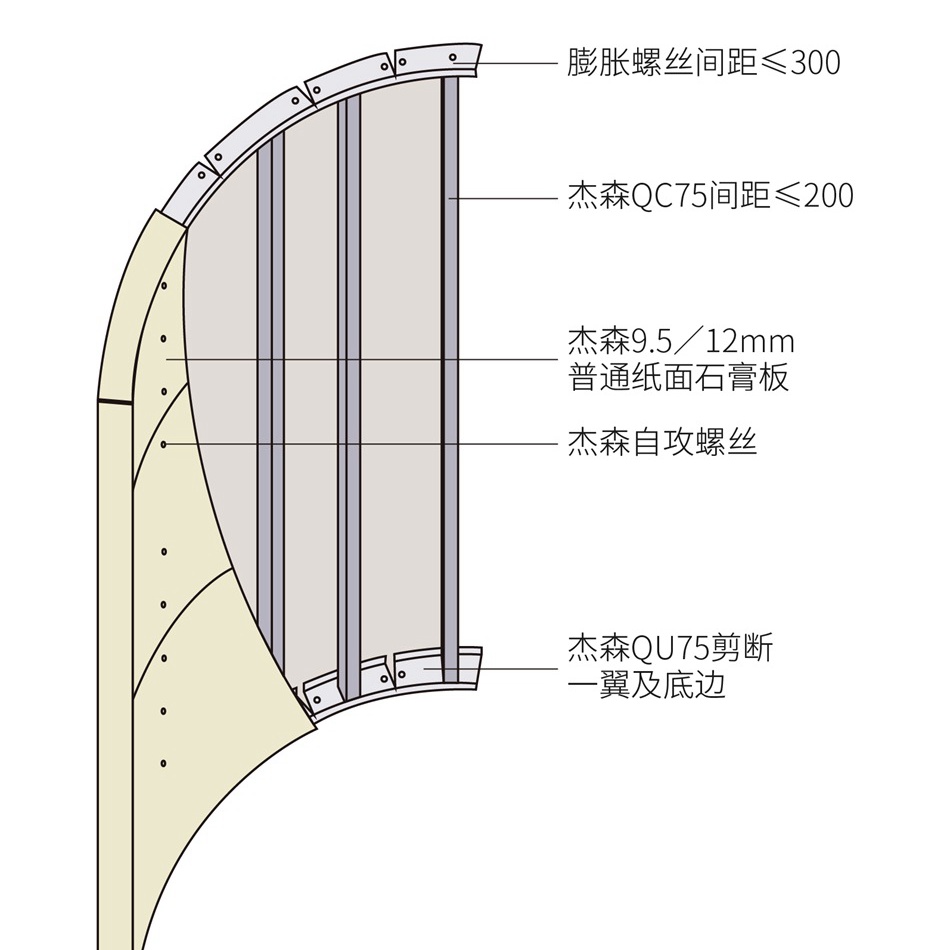

But it is not impossible to achieve a certain degree of curved shape completely with light steel keel, Jason gypsum board curved ceiling partition wall

The system can effectively meet the requirements of this project. As shown in the above figure, using the Jason QU75 keel to cut off one wing and bottom edge and perform fixed angle bending, combined with a C-shaped vertical keel to create an arc-shaped shape, and then covering it with gypsum board that naturally forms an arc with wet water to create the corresponding arc-shaped partition wall; Alternatively, the Jason V-shaped straight card shaped keel can be used, and the curved shaped ceiling can also be smoothly achieved.

In summary, although shapable light steel keel cannot fully replace wooden keel, if you are creating a simple curved shape or using a mixed process of light steel keel and wooden keel for construction, you can still enjoy many benefits of light steel keel. Moreover, Jason's gypsum board editor reminds you that using a gypsum board curved ceiling partition system, combined with Jason's exclusive research and development of superior special boards, will have a better effect, The waterproof, anti mold, and anti cracking effect can reach a new height.

(Some of the images are from the internet. If there is a possibility of infringement, please contact the editor to delete them.)