- High End Gypsum Board System Solution Provider

5 types of decoration substrates, big competition! Which one is more suitable to use?

As an indispensable building material for indoor decoration, the decorative base plate is a very important part of the woodworking node, and also an important part of whether the entire decoration can be fully reflected and durable. For example, the soft and hard packaging of walls, the wrapping of fan coil units, the base layer of partition ceilings, curtain boxes, and light trough bases all require the base layer board to play a supporting and fixing role in the middle layer. Compared to the decorative board and decorative surface, the base layer board plays a significant role as a hidden engineering material that is willing to turn into green leaves. In this article, Jason's gypsum board editor will take five commonly used base boards as examples and analyze in detail their advantages and disadvantages.

1、 Joinery board, also known as large core board. It is spliced with solid wood Flat noodles and covered with two or more layers of plywood

Made. It is currently the most widely used and widely used solid wood base board, with obvious advantages. In fact, the core material of the wooden floor makes the nail holding force level very high, and the plywood cover greatly reduces the possibility of cracking, making it affordable. But the disadvantage is that the environmental performance is average, and it is not fire-resistant. Long term exposure to humid environments can cause significant deformation, which is also a common problem with wooden base boards.

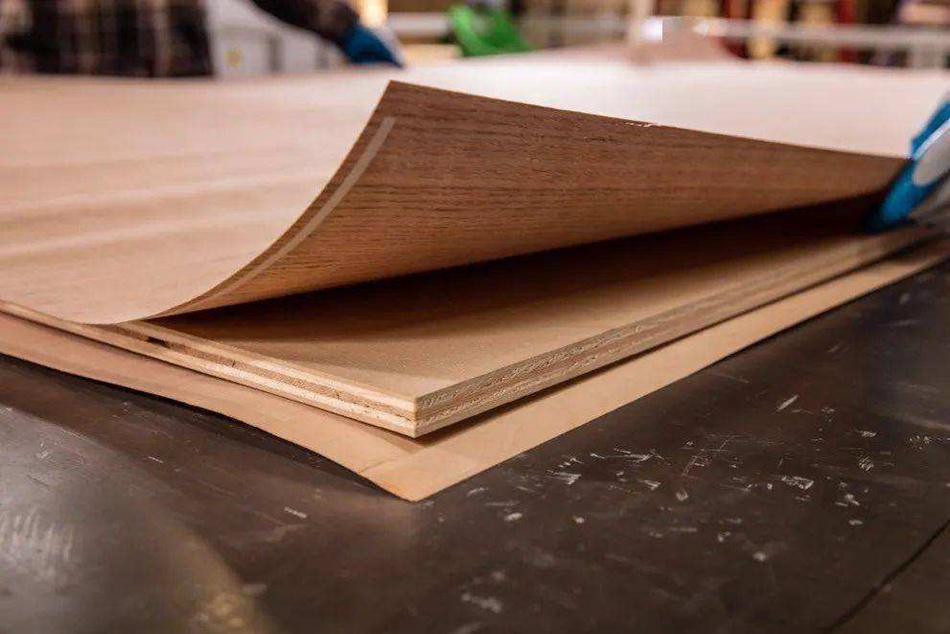

2、 Plywood, also known as thin core board. Compared to blockboard, this is a non solid wood core material, all of which are made of wood or artificial materials

The material is made by hot pressing the thin plate adhesive. Generally, it is formed by pressing odd layers of thin plates, such as plywood, plywood, and heptaplywood. The biggest feature of this type of board is its cheap price, but other performance can only be said to be unsatisfactory. Especially in terms of environmental performance, it is worrying. With the increasing demand for environmental protection from the public in recent years, the market demand for plywood has gradually decreased.

3、 Wood flame retardant board generally refers to particle board with added flame retardants. This type of board is made by adding additives and bonding

Change the defects in wood properties, improve the fire resistance and combustion performance to B1 level, and enhance the nail holding force level of laminated boards. The disadvantage is also particularly prominent, which is that it is difficult to ensure environmental performance, and the grade is low. It has a high usage rate in tooling projects, and is generally rarely used in home decoration.

4、 Europine board, as the name suggests, is a type of wooden board invented in Europe, also known as Germany. It is used like pine trees, eucalyptus trees, and cedar trees

Solid wood of fast-growing trees with high density is made by beating them into thin geometric shapes and then applying glue and hot pressing. Due to its high environmental performance, high density, and nail grip, it is used to replace traditional wooden base boards. Although it is relatively expensive, it performs well in all aspects, with the only drawback being that it is completely non fire-resistant.

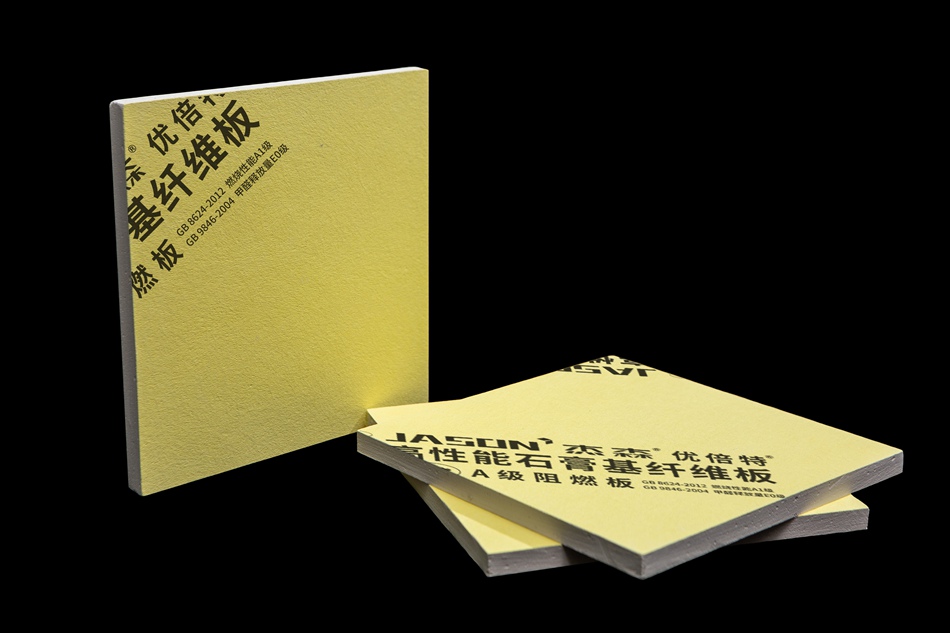

5、 High performance gypsum based fiberboard is developed by Jason gypsum board as a perfect replacement for traditional wooden base boards

Base plate. Upgraded on the basis of gypsum board, adding a large amount of inorganic fibers to enhance the core material properties and replacing traditional gypsum board paper surface materials with fiberglass cover. On the premise of achieving the highest fire resistance and flammability level A1 non combustible, it can also compete with traditional wooden base boards in terms of nail holding force and crack prevention level. Meanwhile, due to the fact that the fiberglass surface is an inorganic material, it can be suitable for environments with relatively high humidity and is not prone to deformation. In addition to its relatively high-end positioning, there are almost no shortcomings in the physical properties of the base board, which can effectively replace the role of wooden base board in indoor decoration and decoration. It can be widely used in scenarios such as partition walls and ceilings, hard and soft base layers, air duct machine wrapping, curtain boxes, light troughs, and fire-resistant cushion layers in flexible coil roof structures.

After comprehensive comparison, the advantages and disadvantages of the 5 types of decoration substrates are shown in the above figure. Objectively speaking, if it is used for home decoration, priority will be given to environmental factors, and Europine board and high-performance gypsum based fiberboard will be chosen. However, in the application of workwear, due to the need for flame retardancy, cost will be considered as a choice in wood flame retardant board and high-performance gypsum based fiberboard. As a manufacturing enterprise with gypsum products as its core, Jason Gypsum Board has always been dedicated to research and development, taking the ultimate needs of users as the driving force for enterprise development.

(Some of the images are from the internet. If there is a possibility of infringement, please contact the editor to delete them.)