- High End Gypsum Board System Solution Provider

A new gameplay for wall leveling, gypsum vs. cement, which is better or worse?

In interior decoration projects, leveling is an essential technique. Especially in home decoration, when homeowners see the item of leveling repeatedly appearing in the budget cost of different areas, and they also need to level it again, their first reaction is often "Is it necessary?". Jason's gypsum board editor tells you that it is very necessary! And if the leveling is done well, it can avoid a series of construction problems in the later stage. Now let's talk about the dry knowledge of leveling construction.

Firstly, leveling needs to be further divided into wall leveling and floor leveling. The main difference lies in the fact that due to gravity, it is easy to use self leveling materials to achieve a more perfect horizontal state in ground leveling, and at the same time, more technical indicators for ground leveling are biased towards load-bearing requirements; However, wall leveling is much more difficult, as it is not only difficult to carry out construction operations, but also requires details such as finding verticality, squareness, right angles, and smoothness. Therefore, if latex paint is used as the surface decoration of the wall, the requirements for wall leveling will be very high. This article mainly introduces the emerging material technology of wall leveling.

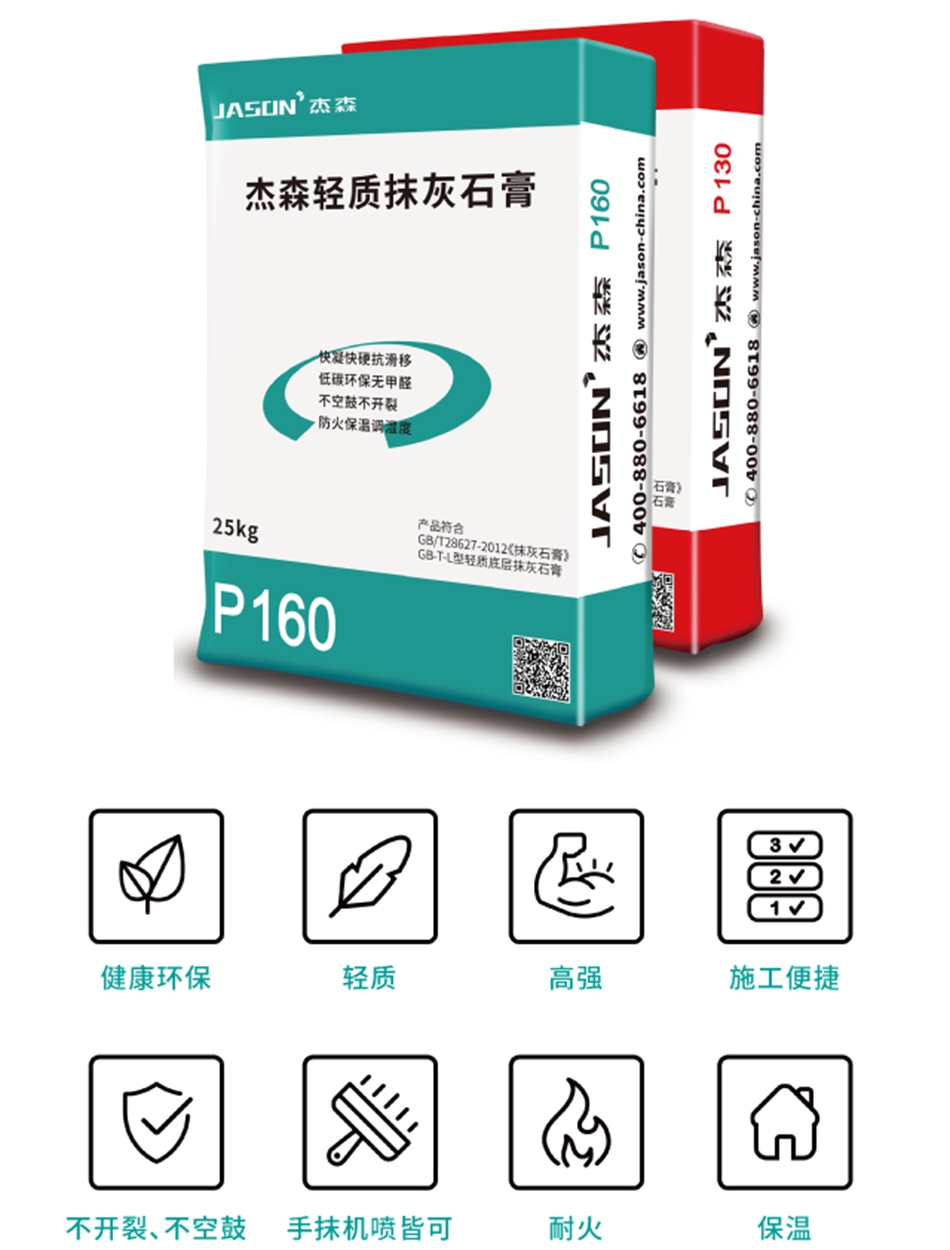

Lightweight plastering gypsum is refined from high-purity desulfurization gypsum, lightweight gypsum materials, polymerization additives, and other raw materials. It is packaged in a dry mix form and only needs to be mixed with water during use. 1. Due to the use of only water and no glue, the problem of harmful gas emissions such as formaldehyde is completely avoided, which completely solves environmental problems; 2. At the same time, due to the excellent drying and curing properties of gypsum materials, even without any adhesive components, they can form good strength and are not prone to hollowing; 3. In terms of construction methods, manual scraping or mechanical spraying can be used to greatly reduce the difficulty of construction, and the process requirements are not high; 4. The time from finishing to drying and final setting of lightweight plastering gypsum is only 2-4 hours, which is more than 80% faster than the final setting time of cement mortar for at least a whole day. This objectively saves a lot of manpower and time costs; The most important point is that the word "lightweight" may seem simple, but in reality, it has significant meaning. The weight of lightweight gypsum plaster on the same area is less than half of that of cement mortar, which not only reduces the overall bearing capacity of the building and the possibility of wall cracking, but also due to the characteristics of gypsum based materials, it can regulate indoor air humidity, and the insulation effect far exceeds that of cement mortar.

In summary, lightweight plastering gypsum can perfectly replace traditional cement mortar in wall leveling operations in all indicators. Not only that, the putty material used for the leveled hanging mesh batch is also gypsum based. Compared to cement mortar, the plastering layer of stone based and gypsum based putty layers themselves are the same raw material. The possibility of wall cracking caused by differences in physical properties of different media during long-term residential use will also be greatly reduced. Jason gypsum board takes gypsum materials as its core, constantly striving to explore new building materials and improve the performance of existing products, providing users with more efficient and environmentally friendly products.

(Some of the images are from the internet. If there is a possibility of infringement, please contact the editor to delete them.)