- High End Gypsum Board System Solution Provider

Are you located along the coast of Jiangsu, Zhejiang, and Shanghai? A permanent solution to the problem of ground subsidence

At the beginning, explain the noun, what is ground subsidence? It mainly refers to the phenomenon of ground subsidence that occurs frequently in coastal cities. It is an engineering geological problem, mainly manifested as regional subsidence and local subsidence, which can cause cracks in the internal and external walls of buildings. In severe cases, it can even cause building tilting and even damage the stability of the foundation. The Yangtze River Delta, Jiangsu, Zhejiang, and Shanghai plain areas are precisely one of the most common areas in China where ground settlement issues are not widespread. How to earthquake resistant and prevent settlement in the foundation and structure of large public buildings has always been a major academic topic, but how to solve the impact of ground settlement on residential buildings has not received much attention. Jason gypsum board, as a production enterprise of building decoration materials, has been tirelessly researching and developing gypsum board system solutions for many years. In this article, we will share the process plan of using gypsum board systems to deal with ground settlement.

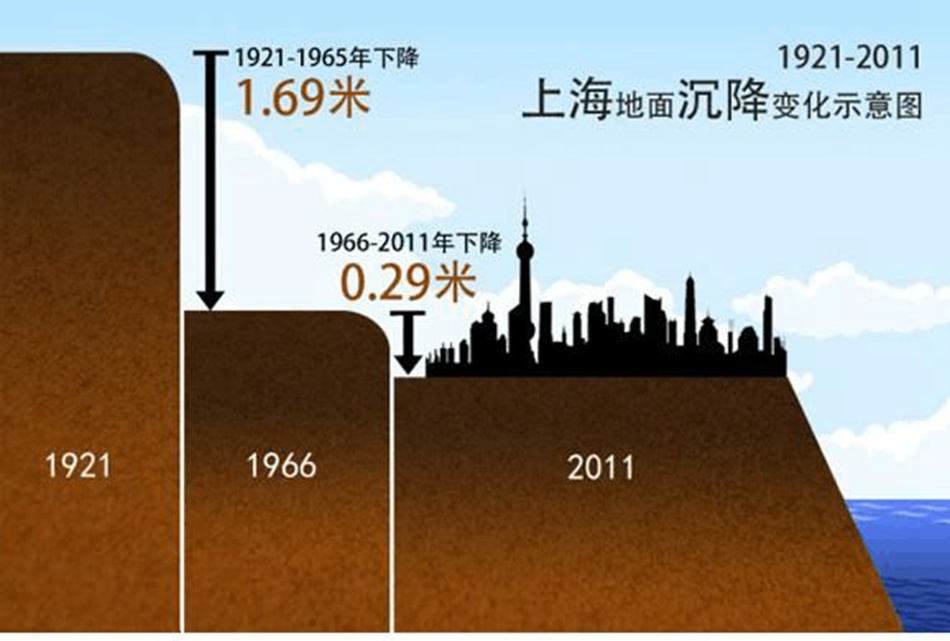

Due to being a plain city formed by sediment impact, Shanghai's land subsidence, a geological hazard caused by blunt cutting, is particularly prominent in Jiangsu, Zhejiang, and Shanghai. According to an authoritative report released by the China Geological Survey, since the discovery of ground subsidence in 1921, the maximum cumulative subsidence in Shanghai has exceeded 2.63 meters since the establishment of the People's Republic of China, affecting an area of over 400 square kilometers. As of the past decade, it has continued to settle at an average rate of over 4cm per year. The harm it causes cannot be underestimated, and for ordinary citizens, the visible and tangible impact is the cracks on the top surface of their residential walls.

For high-rise residential buildings with steel-concrete structures handed over after 2010, as long as the building quality is up to standard, there is currently no significant impact. The most significant impact of ground subsidence is on the multi story residential communities developed between 1990 and 2010, especially those with prefabricated panel structures. Faced with small cracks on the walls in light cases and cracks on the powder masonry layer in severe cases, the top surface of the walls directly peels off, forcing many residents to go crazy and have to renovate. Although the country has responded accordingly, China's first land subsidence prevention and control plan was approved and implemented by the State Council in February 2012. But for ordinary people, it is urgent to prevent the damage and hidden dangers caused by ground subsidence in their homes.

In general interior decoration and renovation projects, the treatment of wall tops has always been an important engineering node. Not only is the process complex, but there are also many types and quantities of building materials used, which are difficult for outsiders to understand. It is also a large white wall that can be made using three processes and ten processes, with a price difference of several times. Why is this? There are various processes involved, including wall scraping, masonry, leveling, interface agents, joint filling gypsum, batch embedding, hanging mesh, second batch embedding, corner strips, latex paint primer, latex paint topcoat, wallpaper, and more. In fact, almost all wall treatment processes ultimately aim to achieve the ultimate goal of preventing cracking. What is the fundamental reason why your home needs to be renovated and renovated again? The high probability is that the top of the wall is cracked, hollowed out, moldy, or peeling off.

Can so many wall treatment processes effectively resist the cracking of walls, especially inner walls, caused by ground settlement? The answer is no. These materials and processes can indeed greatly delay the process of wall cracking, but they are only a delay. After ten or twenty years of residential use and the long-term impact of ground settlement, cracks will eventually occur, only in varying degrees. What is the permanent solution to the problem? Of course there is an answer.

At present, from the perspective of building materials, the only solution that can completely solve the impact of ground settlement on the walls of old buildings is the "gypsum board veneer wall system", and there is no one. The gypsum board U-shaped clip metal veneer wall system is to use U-shaped clips to fix the cladding keel, then cover it with gypsum board (as shown in the above picture), and then carry out paint construction work on decorative surfaces such as latex paint wall cloth art paint on the gypsum board. In this way, almost all problems with the original wall will not affect the light steel keel gypsum board, so naturally it will not affect the final wall finishing layer. The cracking of the wall caused by ground subsidence is equivalent to being covered by the gypsum board layer, bypassing the root cause of the problem, and being invisible is clean.

Of course, using gypsum board veneer wall systems is not perfect either. There may be two questions: 1. Will increasing the thickness of the wall make the indoor space smaller? In fact, there is no need to worry about this. The thickness of the metal veneer wall system is only 4CM, which is within an acceptable range. Moreover, this 4CM thickness can also be pre embedded into strong and weak PVC conduits, eliminating the process of slotting on the original wall and then filling it with powder masonry; 2. Will the cost of making light steel keel gypsum board be higher? In fact, there is no such thing, and even due to the elimination of the steps of slotting, filling, and secondary powder masonry leveling, the overall cost may be lower than that of traditional processes. The time cost saved is equivalent to less labor costs, and it may be more cost-effective overall.

In addition, Jason's gypsum board editor reminds you that if the budget allows, it is best to use Jason's newly developed Uber in the construction of gypsum board veneer wall systems for home decoration ® High performance gypsum based fiberboard. Due to the inorganic fiber core material technology, it has created a strength, durability, nail holding force, and crack resistance performance far higher than ordinary paper faced gypsum boards. It has a 1+1>2 effect in resisting wall cracking caused by ground settlement, allowing home decoration users to truly "once and for all", completely solve the problems caused by ground settlement, and achieve long-term stability.

(Some of the images are from the internet. If there is a possibility of infringement, please contact the editor to delete them.)