- High End Gypsum Board System Solution Provider

Various "cracks" in interior decoration projects need to be properly handled to avoid hidden dangers

In indoor decoration projects, especially for home decoration projects, it is important to distinguish the quality of construction. Only those who are not familiar with the industry will look at the exterior to see the finished surface, while those who are familiar with the industry generally look at three details: waterproofing treatment, edge finishing technology, and gap treatment. Poor waterproof treatment can cause serious economic losses to people and oneself, while poor edge finishing technology can greatly affect aesthetics. The combination of various decorative surfaces cannot naturally transition and can suffocate OCD. And in this article, Jason's gypsum board editor will simply analyze the important detail of gap treatment in decoration, to see which gaps are affecting the final result of decoration, and how to deal with them once and for all without leaving any hidden dangers?

1. Ceramic tile gaps. This is also the most well-known seam, after all, it is one of the most eye-catching and easily visible seams on the completed surface after decoration. Due to the fact that the kitchen and bathroom are also a major expense in home decoration, both glazed tiles, retro tiles, and so-called seamless tiles cannot be separated from the process of leaving and filling gaps due to thermal expansion and contraction. Therefore, decoration owners are particularly concerned about the construction of ceramic tile gaps. From the initial white cement joint filling, to specialized joint fillers, and then to porcelain joint agents and epoxy colored sand, to the resin based beauty joint agent materials widely accepted and loved by the public today. The step-by-step development of research and materials is also due to the increasing demand of homeowners for aesthetic decoration. Therefore, within budget constraints, it is understandable to use more durable and color adjustable beauty stitching agents with a variety of colors to choose from.

2. Gaps in various installation stages. There are many aspects involved, including but not limited to: toilet gaps, bathtub shower room gaps, customized cabinet gaps, aluminum alloy door and window gaps, indoor door frame gaps, skirting line gaps, and so on. As long as there are gaps on the final installation surface before completion, they are considered the same and belong to this column. The treatment of this type of gap is generally carried out using the process of silicone adhesive application. Silicone adhesive also has different colors to choose from, but it mainly uses a semi transparent material commonly known as "sealing glass adhesive", which is a type of ointment that solidifies into a tough rubber like solid with adhesive properties when in contact with moisture in the air. When using silicone adhesive to fill gaps, it is important to note that the gaps must be in a straight line, the surface must be smooth without lumps, and the overall adhesive application must be uniform. This not only has a beautiful appearance, making you completely unaware of the existence of gaps, but also plays a certain role in sealing and waterproofing in many application scenarios. It should be noted that silicone adhesive has a service life. Even if you buy higher grade and more expensive silicone adhesive products, they will still experience aging, hardening, and peeling in about five to six years. At this time, it is necessary to re apply and repair the entire product.

3. The gaps under various newly built wall beams. Simply put, it refers to the newly built light brick walls in a house or the combination of load-bearing beams and walls. This situation is the most likely to cause large-scale cracking of the powder masonry layer at the top of the wall, which not only seriously affects the appearance but also makes repair extremely difficult. Dealing with this type of gap requires the use of two detailed techniques by the bricklayer during the construction process. One is to use the "oblique bricklaying" technique at the top of the newly built wall or at the connection with the load-bearing beam, and the other is to use the "hanging net" technique with wire mesh. The combination of these two processes can effectively avoid the cracking of the later wall powder layer caused by the filling of gaps in newly built walls.

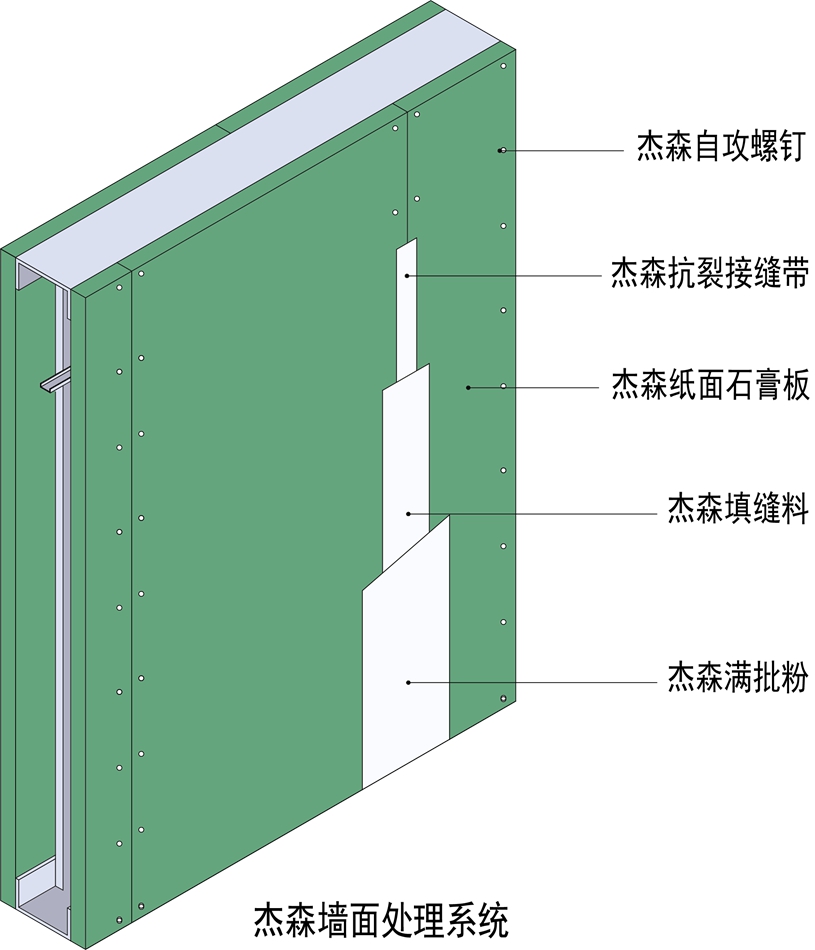

4. The gaps in the gypsum board partition wall ceiling. Indoor decoration will definitely require a large amount of gypsum board partition walls and gypsum board ceilings at the woodworking node. Whether it is lightweight partition wall ceilings, curtain boxes, central air conditioning units, or even replacement soft packaging base boards, gypsum boards will be used. How to deal with the gap between the gypsum board installed on the light steel keel and the board? The process of Jason's non cracking system is as follows: first, ensure that the gap of the gypsum board is reserved at about 5mm, and the self tapping screw is inserted into the board 0.5-1mm without damaging the paper surface. Brush three coats of anti rust paint on the screw, fill the gap with Jason's caulking gypsum, then embed Jason's anti cracking joint paper tape, and apply three coats of Jason's caulking gypsum coating on the joint paper tape. The first coat is 100mm wide, and the second and third coats increase the width by 50mm on each side, Make sure the width is not less than 300mm (as shown in the figure) for the last time. This non cracking system construction process can ensure high durability and prevent the occurrence of cracks and cracks in the gypsum board partition wall ceiling gaps after completion.

In summary, the above four classifications basically cover almost all the details of gap treatment in indoor decoration projects. Jason gypsum board editor suggests that you follow the recommended process and construction procedures in the article to better handle these gaps, increase the aesthetic appearance of the finished surface, improve durability, and ensure that various problems caused by improper handling of gap details are avoided during subsequent occupancy and use.

(Some of the images are from the internet. If there is a possibility of infringement, please contact the editor to delete them.)