- High End Gypsum Board System Solution Provider

When it comes to fire resistant building materials, it is very important for fixtures, after all, as long as the interior decoration of public buildings is subject to fire protection declaration review, it can only operate normally after passing the review. Therefore, whether it is the decoration of office buildings or exhibition halls and shops, building materials with higher fire resistance and better fire resistance performance will be selected as much as possible in order to pass the review. But home decoration and ordinary homeowners have little knowledge about fire resistant building materials, and even have little knowledge about fire safety. In this article, Jason's gypsum board editor will systematically explain what fire resistant building materials are and how to classify fire resistance levels.

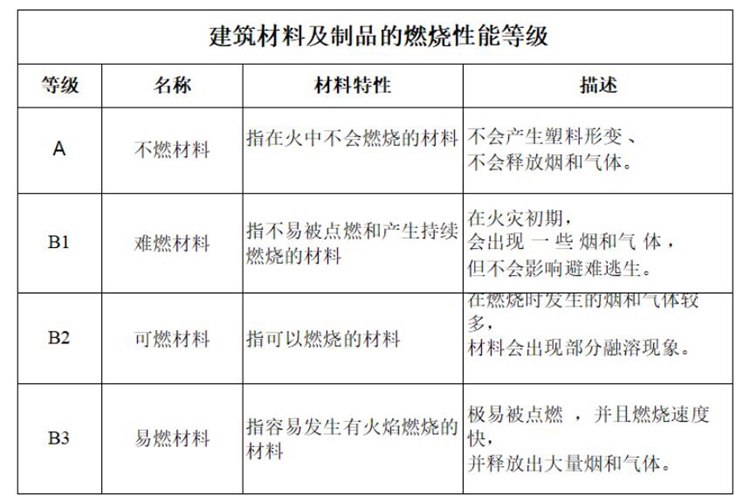

Firstly, the term "fireproof building materials" refers to the building materials used to strengthen the interior decoration design of buildings, standardize the fire protection level requirements of interior decoration, prevent building fires, reduce fire hazards, and protect personal and property safety as the primary purpose. Fire rating is a common term, officially known as the "combustion performance level of building materials and products", mainly divided into four levels: A-grade non combustible materials (further subdivided into A1 and A2 mainly based on parameter height), B1 grade flame retardant materials, B2 grade combustible materials, and B3 grade flammable materials. Please refer to the table below for detailed classification standards:

In fact, for the interior decoration engineering of home decoration and residential buildings, relevant national regulations also have corresponding requirements and suggestions for the use of fireproof building materials and decoration design specifications. However, because there is no need for acceptance review, most homeowners are unaware of this. Specifically, as follows:

① Fixed cabinets in the kitchen should be decorated with materials not lower than B1 grade;

② The ceiling of the bathroom should use A-grade decoration materials;

③ Balcony decoration should use decoration materials not lower than B1 level;

④ Wall hanging, fabric, etc. made of B3 grade decorative materials should not be installed inside the building. When necessary, they should not be placed near electrical circuits, fire sources, or heat sources, or isolation measures should be taken.

From this, it can be seen that even in home decoration, hard decorative materials such as roofs and walls should at least use A-grade non combustible materials or B1 grade non combustible materials, and even soft decorative parts should use at least B2 grade materials. So, which materials belong to Class A and which materials belong to Class B1? Let's provide a detailed list.

A-grade non combustible materials: metal (iron, steel, copper, etc.), cement fiberboard, gypsum based fiberboard (A1), calcium silicate board, rock wool board, fireproof mud and fireproof cotton, fire-resistant paper faced gypsum board (A2), etc;

B1 grade flame retardant materials: ordinary paper faced gypsum board, flame retardant particle board, mineral wool sound-absorbing board, flame retardant plywood, flame retardant density board, aluminum foil composite materials, etc.

Gypsum board, as the most commonly used board for ceiling partition walls, is particularly widely used in the construction of woodworking joints in fixtures and home decoration. Although A2 grade non combustible materials such as fire-resistant paper faced gypsum board are sufficient for use as ceiling and lightweight partition wall coverings in general functional areas, how can places with higher fire safety requirements achieve both high fire safety requirements and aesthetically pleasing decoration effects, as well as durability for longer periods of use?

Through years of dedicated research and development, Jason Gypsum Board has repeatedly experimented and achieved breakthroughs. The independently innovated Jason Uber High Performance Gypsum Based Fiber Board can break through the original fire resistance constraints of paper faced gypsum boards, especially the fiberglass version, which not only far surpasses the fire-resistant paper faced gypsum board that originally emphasized fire resistance, but also has strong fire resistance performance that can pass the test of 4-hour combustion experiments, basically reaching the "ceiling" of fire-resistant boards. At the same time, the high-strength nail holding force of high-performance gypsum based fiberboard core material can not only be used as gypsum board to complete all the functions of the original paper faced gypsum board, but also replace the fine wood board, plywood, density board, and European pine board used as interior decorative base board. The original construction may require one layer of base board and another layer of gypsum board to complete the final finishing of construction process nodes such as curtain boxes, air conditioning unit base, soft and hard packaging base, all of which only require one layer of Jason Uber high-performance gypsum based fiber board.

(Some of the images are from the internet. If there is a possibility of infringement, please contact the editor to delete them.)