- High End Gypsum Board System Solution Provider

The reason why this article refers to the university question is because light steel keel has always been a seriously overlooked category of indoor decoration and building materials. Even industry insiders, designers, and project managers, when it comes to ceiling and partition walls, pay more attention to the brand quality of gypsum board rather than light steel keel. But as a component of the gypsum board system, the knowledge of light steel keel is also worth mentioning. Let's listen to Jason's gypsum board editor explain it in detail below.

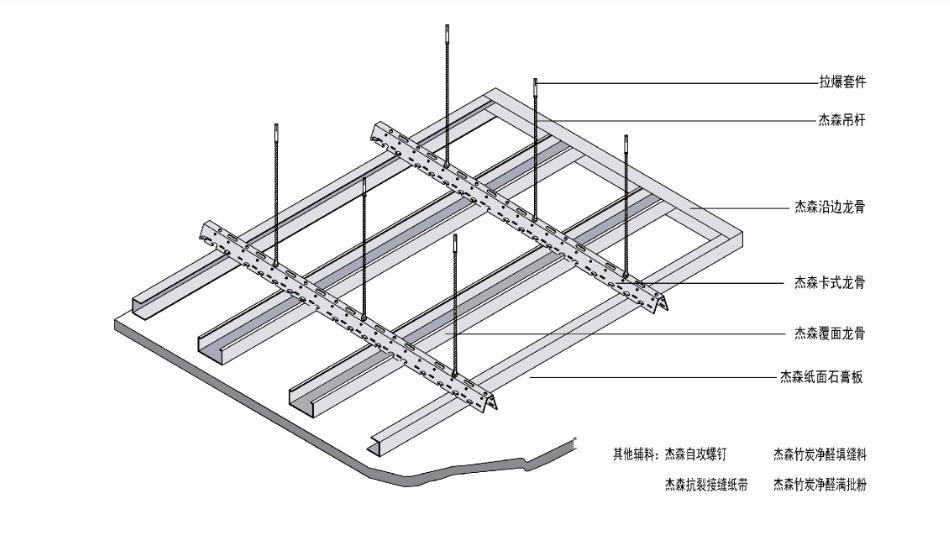

First of all, let me clarify that the functionality that all gypsum board systems can achieve is largely supported by light steel keel structures. For example, a gypsum board partition wall system that can pass a 4-hour open flame combustion test, a gypsum board veneer wall system that can achieve a system thickness of less than 4CM, a gypsum board soundproof wall system that can isolate noise of 50 decibels or above, and so on. In addition to the corresponding functional gypsum board cladding materials, the light steel keel that matches the relevant performance of the system also undertakes the important mission of achieving success. Taking the sound insulation wall system as an example, the unique appearance of the Jason QW sound insulation keel, a patented product independently developed by Jason gypsum board, extends the sound bridge, increases sound power loss, and can greatly improve the performance of the sound insulation wall system.

At the same time, as a non rigid connecting skeleton structure material, the use of high-quality light steel keel materials in the construction of indoor partition walls and ceilings can effectively reduce the cracking and damage caused by indoor humid and dry environments, different material deformation coefficients, ground settlement, and other issues of covering materials such as gypsum boards. Especially for special light steel keel categories like card type keel, there is also a certain ability to cope with minor earthquakes.

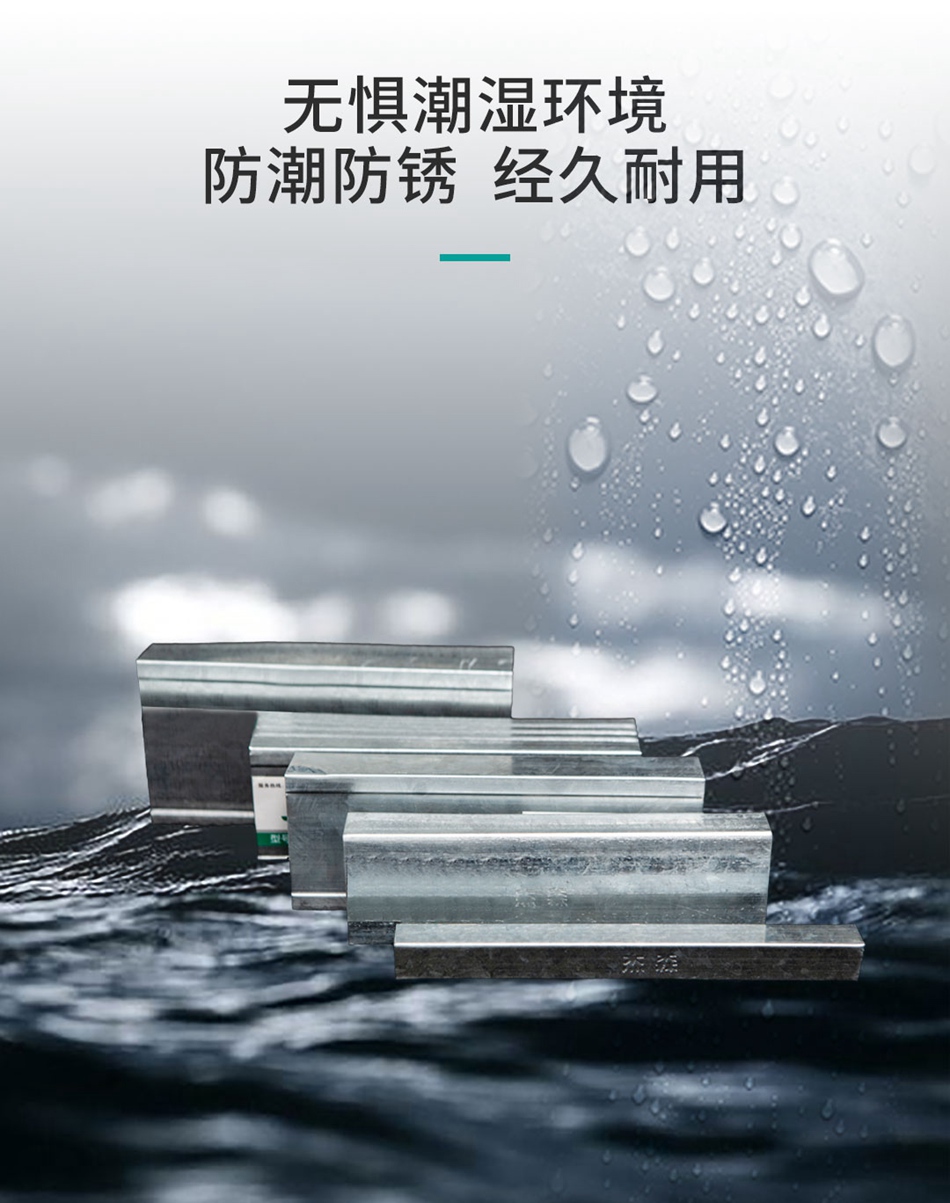

The most important thing is the anti rust ability. It should be noted that the construction of indoor decoration ceiling partition walls was originally mainly based on wooden keel. The reason why light steel keel can comprehensively replace wooden keel is that it has almost lifelong maintenance free rust prevention ability and is not afraid of insect damage. The reason for saying this is that regardless of the tooling, the time limit for secondary home decoration is usually 15-20 years at most. The rust prevention ability of the light steel keel made of hot-dip galvanized sheet and processed by cold bending technology is sufficient to achieve a service life of more than ten years.

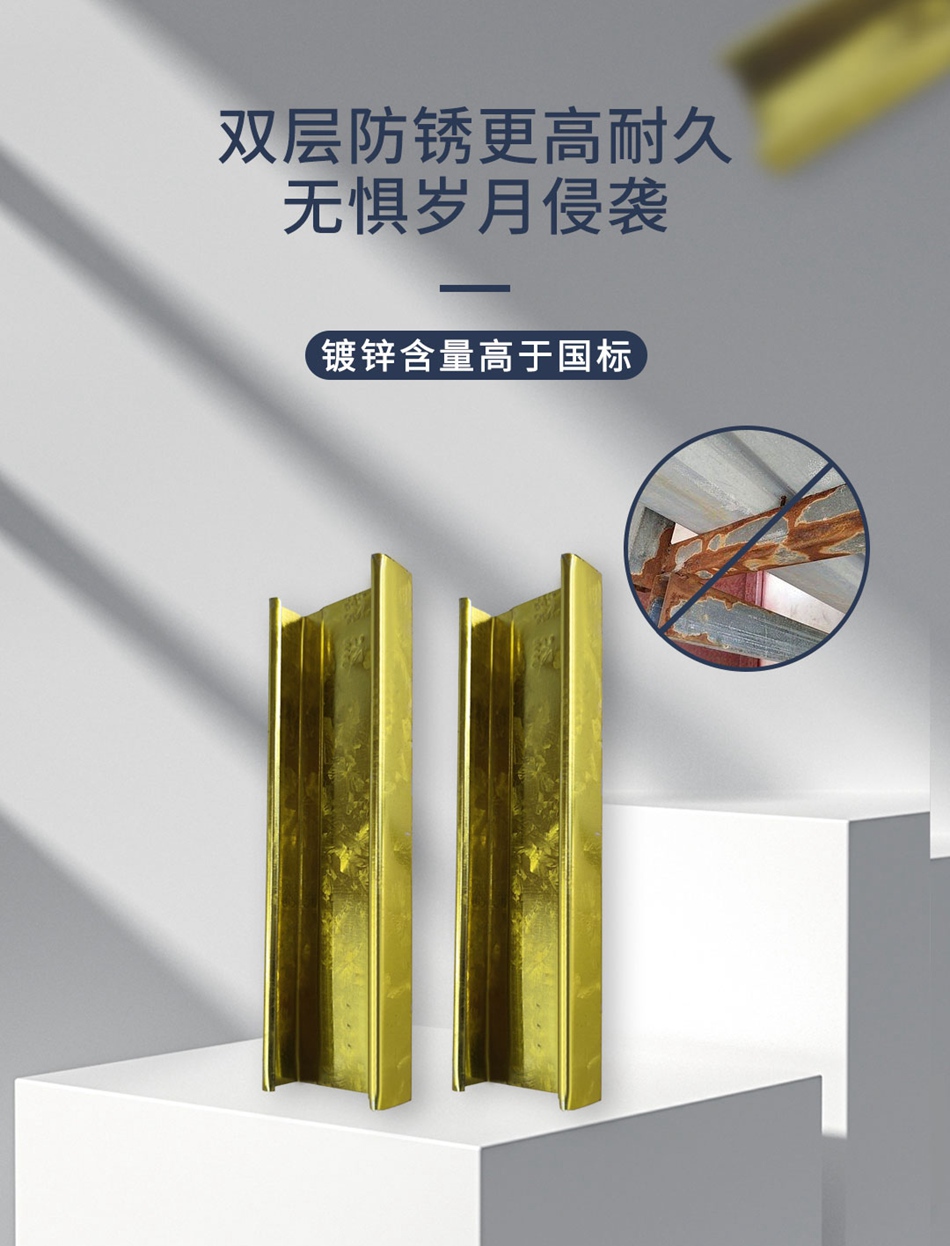

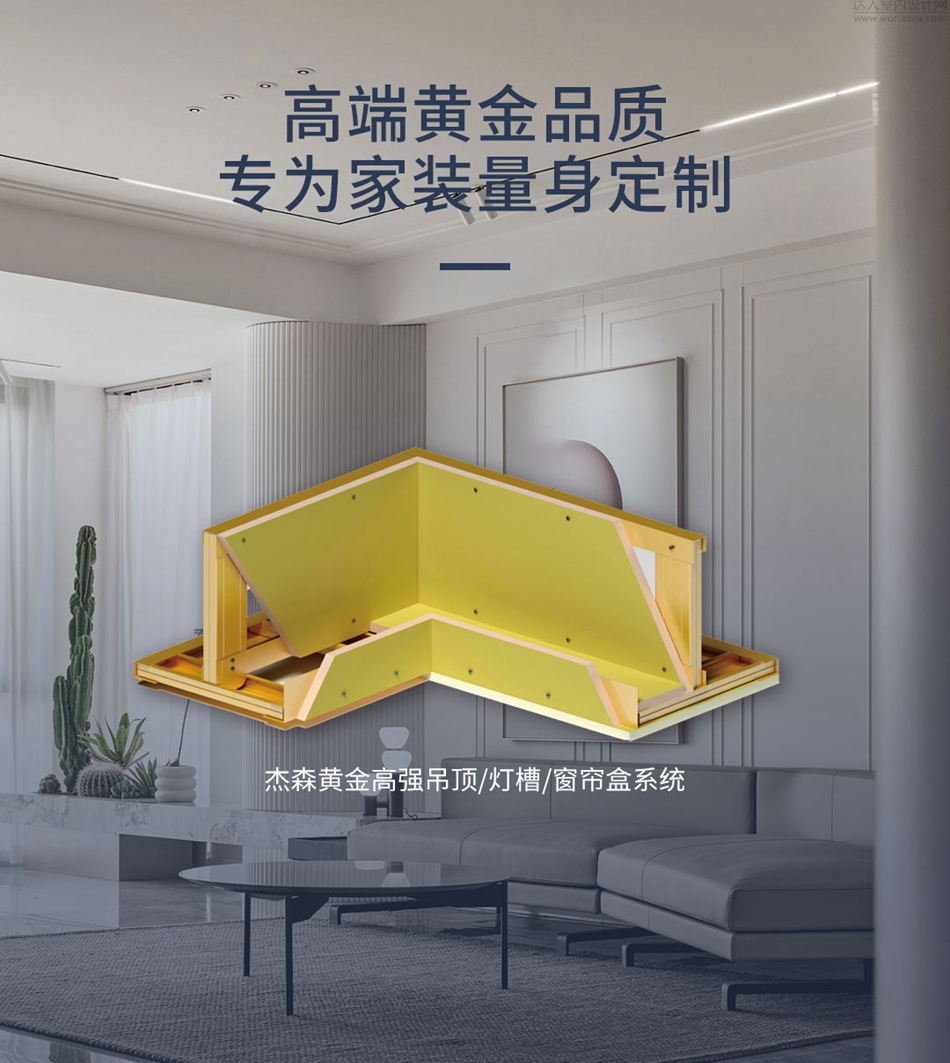

But with the change of consumer consumption habits, the demand for the service life of concealed works is also increasing due to the light decoration and heavy decoration. After a certain period of time, only the decoration surface needs to be updated to completely change the decoration style and functionality. The demand of Party A has gradually become the mainstream. Jason gypsum board has responded to such changes in market demand, actively innovated and developed, and launched a new light steel keel product called "Jason Golden Keel".

Jason's gold keel is different from ordinary light steel keel. It adopts a four element crystal rust prevention layer process, with a gold ratio of 55% aluminum (AL), 43.4% zinc (ZN), and 1.6% silicon (SI) to create a rust prevention ability that is more than 12 times higher than ordinary light steel keel. In this way, the service life of the gypsum board system partition wall ceiling made of golden keel has also been qualitatively improved and improved.

(Some of the images are from the internet. If there is a possibility of infringement, please contact the editor to delete them.)